FUHU Systems Engineering will:

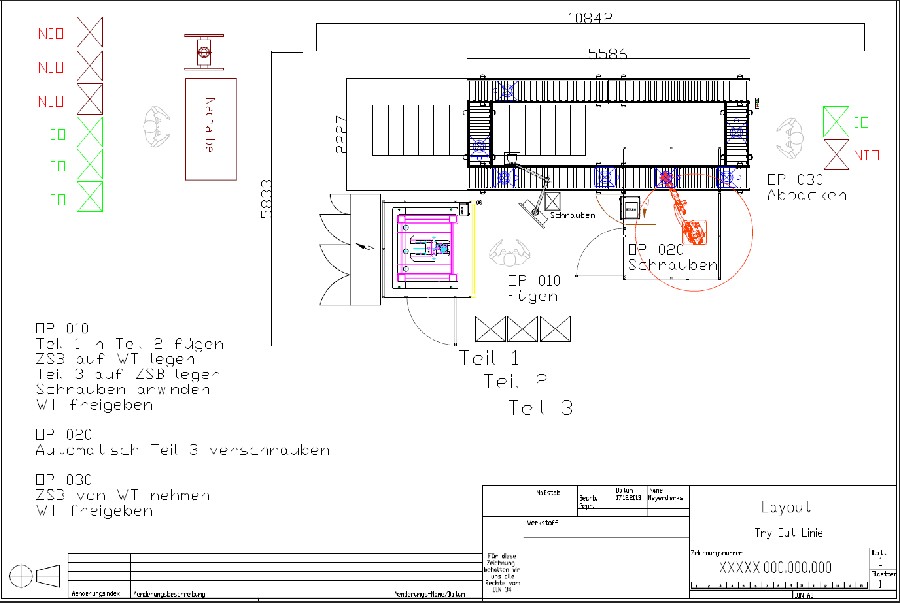

Supply machines and equipment for in house demand.

Provide maintenance and engineering services for in house demand as well as customers throughout China.

Seek partnerships with German and Chinese assembly and test equipment manufacturers in order to increase the nation's capability to develop and manufacture state of the art production equipment.

Train technical personnel in specially designed apprenticeship programs in cooperation with FUHU Powertrain Academy.

Support and consult Chinese customers in acquiring German made assembly and test equipment.

Develop and test new strategies for process engineering.

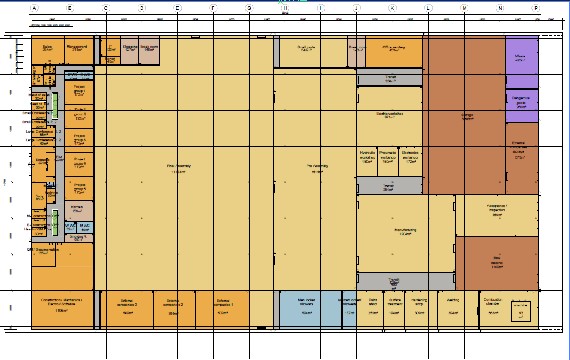

Offer shared services, engineering support and floor space to assembly line and test stand manufacturers who need a temporary base in Shenyang.