Office floor space: 9000 m²

Work shop space: 25000 m²

Office staff: 120

Technical support: 50

Opening: March 2016

In house test center

Test track with 2.5 km straight

Products:

· RWD AT

· FWD AT

· RDM

· FDM

· PTU

Product Development

Our task is to develop 6 - 8 speed automatic transmissions as well as axle differentials for domestic automotive companies in China.

There is a rising demand for high end products like these. Our goal is to design and manufacture a state of the art product line which is competitive with foreign manufacturers.

Our technical expertise comes from Germany. However, we are aware that German technology cannot be applied to the Chinese marked without alterations. Chinese roads, drivers and cars differ a lot from European ones. Therefore, alterations in approach, method and actual design are unavoidable.

Prototype Manufacturing

Prototype parts will be assembled on site, using tools as close to the ones in production as possible and involving production staff. The objective here is not only to manufacture parts for our customers' requirements but also to continuously improve our products and to ensure or designs are fit for manufacturing.

"Even the best product cannot be successful if it is not easily under local and technological circumstances."

Durability Testing

Prototype - and production parts will go through rigorous testing before production release.

The tests will be conducted on state of the art test benches from Germany. Each workshop will contain a test area consisting of 9 test rooms. Extensive databanks will feed machine data back to the design engineers and statistic analytics.

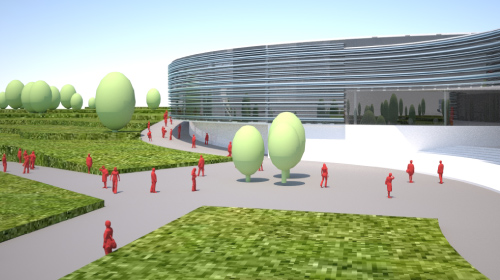

Vehicle Testing

The product is also tested on a test track and will be tested bywell-trained drivers. Our test track consists of a 2.5 km straight in order to allow NVH evalu-

ation in every gear and at every speed.

A part of the test track will be under a roof to allow testing even in winter.

NVH

NVH has for the longest time been considered a sort of "quality policeman" for production. This has changed over the last few years and we intend to

take it one step further. We have a centralized NVH department which is escorting every project from the first sales meetings via design, prototype

phase, production and after sales service. Our customers will be able to talk to the same people throughout the products' lifetime.

And so do our engineers who will be able to rely on a consistent NVH strategy specifically designed for each product.